The oxyfuel torch is an equipment designed to mix the fuel gas with oxygen. They need to be in an ideal proportion to give the right kind of flame. They also direct the high-speed oxygen jet to the cutting nozzle.

Torch components

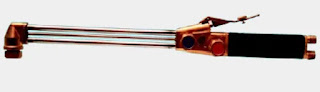

The torch consists of:

- (1): Valves

- (2): Torch body and gas pipes

- (3): Support

The picture below shows an automatic cutting torch.

Types of torches

Torches can have the cutting tip mounted at 90º in relation to its base for manual processes. They can also be straight for coupling in automatic cutting machines.

In addition to that, there are combined torches. They are used in places where there is an alternation between cutting and welding operations, such as in maintenance workshops.

In such a case, a cutting device is mounted to a welding torch, consisting of:

- A mixing chamber.

- Separation system.

- Valve for control of oxygen.

A combined torch can be seen in the picture below:

(4): Welding extension.

(5): Cutting extension.

(6): Torch cable.

Another manual torch variant

Some torches come with separate circuits for oxygen and fuel. So the mixture is only made in the cutting nozzle:

And finally there are the automated cutting torches.

They allow complete separation of the O2 all the way through, by having two separate oxygen inlets. It allows:

- The regulation of the O2 and flame pressure.

- The oxygen needed for the cut to go into separate regulators.

This allows specific adjustments for each use. So we can have different pressures for different uses.

Regarding the mixing of gases in a torch, this can be done in different ways.

The gases can only be mixed in the cutting tip, as shown in the picture above, or in the torch itself.

The mixtures in torches can be by oxygen injection or mixing chamber.

The principles of injector and mixing torches are illustrated in the picture below:

(7): Injectors.

(8): Mixers.

In injector torches, the combustible gas is sucked through the high velocity of oxygen through a venturi.

In mixers, the combustible and oxidizing gases reach the mixing chamber at identical pressures through the regulation of the valves.

In nozzle mixing system, the gases are supplied separately to the nozzle, where they are finally mixed.

The mechanized cutting torch has an elongated body. It extends from the gas control valves to the cutting nozzle.

In this torch, the cut-off oxygen valve can be activated manually or automatically from a central command. Its use is recommended for jobs where standardization and uniformity of cut is required, such as in cases of mass production.

Cutting nozzles

The nozzles are mounted on the torch head to keep the mixtures of the gases separated. They also lead them to the surface to be cut (through holes in its interior).

The main and most important dimension of the cutting tip is the inner diameter of the cutting O2 channel.

Through this orifice, the correct pressure and oxygen flow are balanced for the thickness to be cut. So the nozzle must be determined as a function of the thickness.

The possible thickness limits to be cut by the nozzle are determined by the choice of orifice diameter.

The shape of the oxygen channel is also important as it determines the restriction that the gas will meet. Consequently, the velocity of the gas and of the entire process will also be influenced.

The picture below shows some of the different shapes of oxygen channels:

Cutting nozzles are available in a wide variety of types and sizes. The choice of nozzle must take into account the following criteria:

- Material to be cut.

- Thickness.

- Fuel gas.

Each manufacturer has its own technical specifications for its nozzles. This influences the cutting result in terms of:

- Quality.

- Cutting speed.

- Gas consumption.

- Total cost.

It is important to note that the nozzle is perhaps the lowest cost component in an automated cutting system. But when it is misused, it has the greatest potential to increase the total cost of operation.

You shouldn't clean with the introduction of needles as it may increase the internal diameter of oxygen channel. You should cleaning it with chemicals that remove scale.

Learn Welding

Citation

When you need to include a fact or piece of information in an assignment or essay you should also include where and how you found that piece of information (Oxy Fuel Cutting Torch).

That gives credibility to your paper and it is sometimes required in higher education.

To make your life (and citation) easier just copy and paste the information below into your assignment or essay:

Luz, Gelson. Oxy Fuel Cutting Torch (Types, Components and Nozzle). Materials Blog. Gelsonluz.com. dd mmmm. yyyy. URL.

Now replace dd, mmmm and yyyy with the day, month, and year you browsed this page. Also replace URL for the actual url of this page. This citation format is based on MLA.

COMMENTS