Definition

- Coated electrode.

- Rods.

- Solid wires (bare electrodes).

- Tubular wires (electrodes).

- Fluxes.

- Shielding gases.

- Consumable rings.

Selection of consumables

- Base metal.

- Geometry and joint type.

- Part thickness to be welded.

- Welding position.

- Welder skill.

- Productivity.

- Welding costs.

- Type of energy source.

Understanding AWS Specifications - American Welding Society

|

AWS |

ASME |

|

A 5.1 |

SFA 5.1 |

|

A 5.4 |

SFA 5.4 |

- SFA-5.1/SFA-5.1M - Carbon steel electrodes for manual arc welding with coated electrode (SMAW).

- SFA-5.2 or SFA-5.2M - Low alloy and carbon steel rods for OXI-GAS (OFW) welding.

- SFA-5.4 or SFA-5.4M - STAINLESS steel electrodes for manual arc welding with coated electrode (SMAW).

- SFA-5.5 or SFA-5.5M - LOW ALLOY steel electrodes for manual arc welding with coated electrode (SMAW).

- SFA-5.9 or SFA-5.9M - Bare electrodes and STAINLESS steel rods.

- SFA-5.12 or SFA-5.12M - Tungsten electrodes and their alloys for arc welding and cutting.

- SFA-5.17 or SFA-5.17M - Carbon steel electrodes and flux for SUBMERGED ARC welding (SAW) .

- SFA-5.18 or SFA-5.18M - Carbon steel electrodes for shielding gas arc welding (GMAW).

- SFA-5.20 or SFA-5.20M - Carbon steel electrodes for arc welding with tubular wire (FCAW).

- SFA-5.22 or SFA-5.22M - STAINLESS steel electrodes for arc welding with tubular wire (FCAW) and flux-core stainless steel rods for TIG welding (GTAW).

- SFA-5.23 or SFA-5.23M - Low alloy steel electrodes and fluxes for submerged arc welding (SAW).

- SFA-5.25 or SFA-5.25M - Carbon steel or low alloy electrodes and fluxes for electroslag welding (ESW).

- SFA-5.26 or SFA-5.26M - Carbon steel or low alloy electrodes for electrogas welding (EGW).

- SFA-5.28 or SFA-5.28M - Low alloy steel electrodes for arc welding with shielding gas (GMAW) or rods for TIG or plasma welding (PAW).

- SFA-5.29 or SFA-5.29M - Low alloy steel electrodes for arc welding with tubular wire (FCAW).

- SFA-5.32 or SFA-5.32M - Protective GASES for welding.

- SFA-5.36 or SFA-5.36M - Carbon steel or low alloy electrodes for arc welding with flux core flux cored wire (FCAW) or METALLIC CORE.

Differences between "specification" and "classification"

The specification tells us the consumable's requirements according to their use.

To meet an AWS specification, consumables must meet specific requirements, for example:

- Mechanical properties of the deposited metal (tensile, bending and impact tests).

- Chemical composition of the deposited metal.

- Absence of defects of the deposited metal (Radiographic examination).

The AWS specification establishes the test conditions for the consumables to be carried out by the manufacturer.

Manufacturers need to verify that the weld produced has the minimum mechanical properties required.

In addition to classifying the consumables, the specification also determines that they meet manufacturing requirements:

- Acceptance criteria;

- Chemical composition of the deposited metal;

- Mechanical properties of the deposited material;

- Packaging;

- Identification;

- Warranty.

On the other hand, the AWS classification organizes consumables by its:

- Mechanical properties (resistance limit, impact);

- Chemical composition;

- Coating.

Also, the classification provides a logical designation. This allows us to easily identify its main characteristics.

Therefore, the difference between specifications and classification is:

The AWS specification accurately determines the characteristics of a consumable and gives guarantees regarding its properties.

While:

The AWS classification presents a logical way to designate a consumable.

To make it easier for you to understand, think of an analogy with a hospital.

Your first name would be the classification and your record would be the specification.

Please remember that your form has all your information such as full name, weight, height, address, among others...

In theory you could make another person just like you if you follow all the details on the sheet (specification).

It is not possible to do the same with your name (classification).

As a matter of fact, you may notice that several people may have the same name as you (classification) but differ in weight, height, etc. (specification).

AWS Classification

In the AWS specifications, consumables are designated by a set of numbers and letters with one of the following prefixes:

Most common:

- E – Electrode (electric arc welding);

- R – Gas welding rod;

- ER – Bare electrode (wire) or rod;

- T – Tubular electrode.

Less common (special processes):

- F – Flow (submerged arc);

- Q – Tape (electric arc welding);

- C – Composite electrode (electric arc welding);

- B – Brazing filler metal.

Types of welding consumables

Used in Gas Welding

This welding process uses thermochemical energy.

- Combustible gases – Acetylene, Propane, Butane, Natural Gas, among others;

- Oxidising gases – oxygen, atmospheric air (almost never used);

- Sticks;

- Flux.

Used in electric arc welding

The following welding processes uses electrical energy.

GTAW

Electric arc is established between a refractory electrode (non-consumable) and the piece to be welded.

Note: This welding process was initially developed to use inert type gases (eg argon and helium) to protect the fusion pool and the electric arc from the action of gases found in atmospheric air.

For this reason, he was named "Tungsten Inert Gas".

Later, there was an introduction of active gases (CO2 and O2) in inert gases, along with the development of tungsten electrodes linked to thorium oxides, cerium, among others.

This welding process is now called "Gas Tungsten Arc Welding" (GTAW).

- Rod (Manual GTAW) and non-energized wire (Mechanized GTAW).

- Pure gases (Argon, Helium)

- Gas mixtures (Argon and/or Helium + CO2; Ar + O2; Ar + CO2 + O2).

SMAW

It means: Manual Welding with Coated Electrode.

- Electrode (Coated).

SAW

Electric arc is established between a bare consumable electrode and the part to be welded.

It means: Submerged Arc Welding.

- Electrodes (bare and composite) and flux.

GMAW

It means: Welding with Gas Protection.

- Solid (naked) electrode (or wire) and metal-cored tubular wire.

- Pure gases and gas mixtures.

FCAW

It means: Tubular wire welding with (or without) gas protection.

With Gas Protection:

- Tubular electrode (or wire).

- Pure gases and gas mixtures (see GMAW welding process).

Without Gas Protection (Self-protected):

- Tubular electrode (or wire).

Grouping consumables (electrodes, wires, fluxes, etc.)

It is important for you to understand what is the "F number". So first of all:

"F number" is different than "P number".

"P number" refers to the base material and I will cover it in my base materials article.

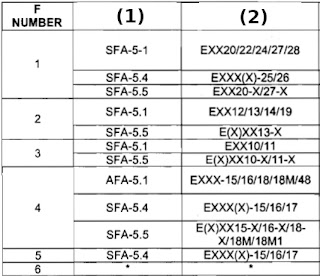

The ASME Section II Part C code uses the same specification and classification system as AWS. Like for example:

Specification (1):

ASME SFA-5.1 = AWS A5.1

Classification (2):

E7018 = E7018

Note: ASME is the American Society of Mechanical Engineers and AWS is the American Welding Society. When we talk about ASME or AWS, we are actually talking about the standards that these entities wrote.

Using the AWS specifications, the ASME code groups consumables and designates them a common F number.

This designation ranks consumables according to the difficulty they offer to welders.

In another words, it is reasonable to expect that a consumable with "F number" 4 is more difficult to use than an "F number" 1.

Note: "F Number" 6 groups various consumables such as:

- Solid and tubular wires for welding with gas protection or not.

- GMAW.

- FCAW.

- GTAW welding rods.

- Wires and fluxes for SAW submerged arc welding.

- Wires for FOW oxy-gas welding, etc.

This grouping aims to reduce, whenever possible, the amount of performance qualifications.

This does not mean that consumables can indiscriminately replace each other in some qualification tests.

I talk about it in my “Qualification of Procedures and Welders” article.

Learn Welding

Citation

When you need to include a fact or piece of information in an assignment or essay you should also include where and how you found that piece of information (Welding Consumables).

That gives credibility to your paper and it is sometimes required in higher education.

To make your life (and citation) easier just copy and paste the information below into your assignment or essay:

Luz, Gelson. Welding Consumables (Definition, Selection, Groups). Materials Blog. Gelsonluz.com. dd mmmm. yyyy. URL.

Now replace dd, mmmm and yyyy with the day, month, and year you browsed this page. Also replace URL for the actual url of this page. This citation format is based on MLA.

COMMENTS