I've already talked about yield strength and tensile strength in other articles. These stresses represent the materials that were tested in a tensile test.

But the actual material that will be used may have imperfections or particularities that reveal a lower resistance than that revealed in the tests.

Another typical problem is the user's misuse or abuse. Have you ever seen an elevator with more people than allowed?

To compensate for these practical difficulties, the engineer must limit the stress of the material to a safe level.

This safe level is known as Allowable Stress and is obtained with the aid of the Safety Factor (F.S.) or Safety Coefficient (C.S.).

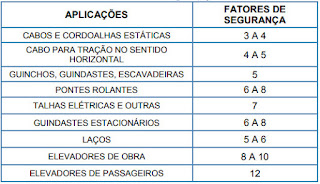

The choice of factor of safety is made on the basis of the calculation standards or, in the absence of them, by the designer engineer himself.

The engineer can choose the F.S. based on his experience, according to some criteria.

It is an analysis that needs to be very careful because it should take into account several factors, such as:

The safety factor is always a number greater than 1 in order to avoid failure.

You may use the yield or the tensile limit, depending on the philosophy of calculation of the designer and technical standards.

CS is the factor of safety.

Even having a standard to follow it's important to have common sense. The standard (often) is not able to predict all uses and applications.

Below are some allowable stresses (Tension, Compression, Shear and Bending) for building materials:

But the actual material that will be used may have imperfections or particularities that reveal a lower resistance than that revealed in the tests.

Another typical problem is the user's misuse or abuse. Have you ever seen an elevator with more people than allowed?

To compensate for these practical difficulties, the engineer must limit the stress of the material to a safe level.

This safe level is known as Allowable Stress and is obtained with the aid of the Safety Factor (F.S.) or Safety Coefficient (C.S.).

Safety Factor or Factor of Safety

Factor of safety is used in sizing the building elements to balance the build quality (safety) and cost.The choice of factor of safety is made on the basis of the calculation standards or, in the absence of them, by the designer engineer himself.

The engineer can choose the F.S. based on his experience, according to some criteria.

It is an analysis that needs to be very careful because it should take into account several factors, such as:

- Material to be applied;

- Loading frequency (Number of times the load is applied: has fatigue?);

- Acting environment;

- Type of loading for which it is projected or future;

- Break mode that may occur;

- Deterioration that may occur in the future due to lack of maintenance or natural causes;

- The importance of a certain member for the integrity of the whole;

- Influence on the function to be performed by the machine;

- Risks of life or property;

The safety factor is always a number greater than 1 in order to avoid failure.

Calculation of Allowable Stress

The calculation is given by the following formula:You may use the yield or the tensile limit, depending on the philosophy of calculation of the designer and technical standards.

CS is the factor of safety.

Allowable Stress (Table)

In some standards it is not necessary to choose the safety factor because the standard already gives you the value of the allowable stress.Even having a standard to follow it's important to have common sense. The standard (often) is not able to predict all uses and applications.

Below are some allowable stresses (Tension, Compression, Shear and Bending) for building materials:

COMMENTS