What is impact testing?

The impact test is used to understand and evaluate the fragility of metals. The fragility of metals is associated with the characteristic or property that this metal has to achieve rupture (or fracture) without suffering appreciable deformation.The test gained importance from world war II, when ships began to use welded plates in place of traditional riveted construction.

Until then, this fragile behavior was not understood because it could not be predicted by any other test performed, such as the tensile test.

The tensile test is a uniaxial/uniaxial resistance test normally performed at room temperature and therefore was not representative of the working conditions that the "liberty" ships of the United States were undergoing:

- Lower temperatures;

- Triaxial stress state (Voltage on the three axes - X, Y and Z);

- Load applied dynamically (impact);

Impact resistance is greatly affected by temperature but also by conditions that cannot be easily implemented in a common tensile test:

- Existence of cracks or notches;

- Speed of loading;

Even using dubious materials, with sufficient strength to withstand a certain application or load, it was found in practice that a dubious material can break weakly after a given temperature.

The impact test consists of subjecting a standardized, patterned test body to a bending caused by impact by a hammer in the figure below.

The impact test allows to obtain the energy used in the deformation and fracture of the test body. This energy is the measure of the difference between the initial height of the h pendulum and the maximum height reached after the rupture of the h' test body.

Note that the smaller h', the more energy was absorbed by the test body. On the other hand, the lower the absorbed energy (greater h'), the more fragile the behavior of the material at that temperature.

Purpose of the impact test

The impact test is applied by requirement of standards (ASME, AWS, DIN, ISO, etc.) and we have several reasons to use it.One of the reasons is to evaluate the materials in equipment that will operate at low temperatures. More specifically, it is used in the evaluation of the fragile behavior of materials and acts as an auxiliary tool for the study of the dúctil-fragile transition temperature of the materials.

The result of this evaluation, however, has limited meaning and interpretation and its result is not conclusive. For this reason, the test should be restricted to the comparison of tested materials under the same conditions.

For more quantifiable results, the CTOD assay and, alternatively, the drop weight test should be used.

The explanation of the limitation of the impact test is due to the fact that the components of triaxial stresses present in the test body during the test cannot be measured satisfactorily because they depend on several factors.

Thus, we cannot relate the energy absorbed by the test body to the behavior of the metal to any impact, which would only happen if the entire piece was tested in working conditions.

You can also use the impact test to assess the success (or failure) of manufacturing conditions such as welding or imposed heat treatment cycles.

Another very common application is also for validation of the welding procedure used in a given welded joint. It is not enough to know if the material is suitable, the weld should also be evaluated.

Types of specimens

The test body is standardized by standards (ASTM A370 for example) and provided with a notch of measures also standardized to allow the location of the fracture and produce a triaxial state of stresses.The specimens generally used for performing the impact test are: charpy specimen and izod specimen, both specified by ASTM E23 standard.

Of these two, the type of cp (proof body) charpy type is the most used without a doubt. It is so used that the impact test is sometimes called "charpy" (pronounced with stronger sound in Y).

Charpy Test Body

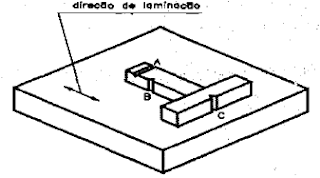

Charpy specimens are classified as type A. B and C, with square section of 10 mm, length of 55 mm and notches in the center of the specimen.Type A has the Notch in the form of V, type B in the form of a keyhole and type C in the form of U. Charpy type specimens are supported centrally and the distance between these supports is 40 mm.

The figure below shows the shape, dimensions, and notches of these three types of specimens.

The Charpy test body is supported on the test machine.

Izod Test Body

The Izod test body has a square section of 10 mm, length of 75 mm, notch at a distance of 28 mm from one end, v-shaped.The specimens with deeper notches (Example Izod and Charpy type A) are used to show the difference in absorbed energies in the most dubious metal tests. These cps tend to cause fragile fractures more easily.

In testing of more fragile materials, such as FoFo (cast iron) or cast metals under pressure, specimens usually do not require the notch. That's because the material is already naturally more fragile.

The Izod test body is set (stuck) in the test machine.

Reduced specimens

In the case of materials whose dimensions do not allow the manufacture of normal specimens (thickness less than 11 mm), it is possible to remove the reduced specimens. However the length, slot radius and notch angle of the test body remain constant.Notch Machining

We must have adequate equipment and slot profile control means, as a small variation in slot machining can introduce major errors in the test result.Note: Petrobras through its standards requires the verification of the notch in a profile projector before performing the charpy impact test for example.

The slot can be used by means of a broached, planer or milling machine, and its profile must be controlled by a profile projector.

Whenever I go to follow an impact test I ask the operator to put a test body on the profile projector so I can assess the compliance of the notch.

Notches should be machined after heat treatment, where applicable. Slotted specimens in the form of a "keyhole" should have the circular hole carefully opened with low cutting speed.

The groove cut can be performed by any applicable method, but so that the hole surface is not defective.

Removal of Specimens

The standards specify the place of removal of the specimens, since their orientation and direction for the preparation of the notch imply significant changes in the test results.We have following three positions of removal and/or positioning of the notch on Charpy specimens, taken from different positions of a steel plate.

Three possibilities of removal and positioning of the notch in Charpy specimens

Submitted to the impact test, these bodies presented three different curves, as shown in the following graph.

In the body A, the notch is transverse to the fibers of the material. Curve A shows that this was the test body that presented the greatest amount of absorbed energy.

The test body C, which has notch in the direction of fiber (which favors shear), has the lowest possible energy absorption.

The B-proof body also has a cross notch. Only, in this case, the notch crosses the core of the plate, cutting all the fibers across.

The curve is in an intermediate situation compared to the other two. This relationship between the curves remains constant, whatever the temperature of the test.

Testing Technique

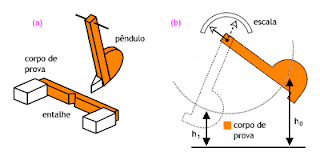

The impact test can be seen from the scheme given below.A standardized test body with a notch is broken by the action of a hammer in the form of a pendulum (a). The principle of operation can be analyzed by the side view (b) of the same figure.

It is assumed that the pendulum is taken to such a position that its center of gravity is at a height h0 in relation to a reference in such a way that its kinetic energy at the point of impact has a fixed and specified value. The hammer is released and hits the test body from the opposite side of the notch.

Disregarding the air resistance and friction at the pivot, once released and in the absence of the test body, the pendulum should reach the same height on the other side by the principle of energy conservation.

After breaking through the test body, the hammer rises to a height that is inversely proportional to the energy absorbed to deform and break the test body. Thus, the lower the height reached by the hammer, the more energy the test body absorbed. This energy is read directly into the test machine.

If the test body is inserted and ruptured by the impact of the pendulum, the energy absorbed in this operation causes the pendulum to reach, on the other side, a maximum height h1 less than h0. That is, the impact resistance of the material is given by the difference between the potential energies in h0 and h1.

In practice, the instrument has a graduated scale, with maximum value indicator, for direct reading of the energy difference. Because it is energy, the impact resistance in reports is usually recorded in Joules (J). However, the energy absorbed by the test body can also be expressed in kgf/m (kilogram-force per meter) or lb/ft (pound per foot) or J (Joule). Some older machines in Brazil usually display the energy in kgf/m and the conversion to Joule is required.

In the charpy assay, the test body has a central notch and is supported at both ends. The impact takes place on the center as shown above.

The most common notch is type "V", but there are also notches in the form of "U" or hole-ending slit. The dimensions for the type V notch are:

- Length 55 mm;

- Section 10 x 10 mm;

- Notch at 45º;

- Depth 2 mm.

Equipment

The test equipment is basically composed of a pendulum (hammer) that is released in free fall of a fixed height, a support site of the test body and a measuring instrument, which contains a dial with graduated scale.This dial allows you to determine the energy absorbed to break through the test body, by means of the difference between the initial height and the final height reached by the pendulum.

Considerations about the test

The test temperature is directly related to the results obtained in low and medium strength material and should therefore be recorded in the result along with the type of test body that was tested.Impact tests are usually specified for low temperatures, but can also be performed at ambient temperatures or even under ambient temperatures.

In cases where the test temperature is not room temperature, the specimens must be inserted into the machine and ruptured within five seconds (so that there is no significant temperature variation). In addition to this, the heating and/or cooling medium has to have a control for the maintenance and homogenization of temperature.

The charpy test is the most recommended because it is the simplest positioning on the machine. The handling of the cps can be done with the use of a tenacious (claw type) suitable for its dimensions. It is also the cheapest impact test compared to tests like CTOD.

Some care should be taken when performing the impact test. For example, before the start of the test, the machine must be checked by means of a free oscillation of the pendulum, so that the pendulum released in free fall indicates a zero energy on the machine display.

If this procedure reveals that the display records some energy value, then this value should be removed from the results obtained during the test with the test body.

It is not recommended to perform only an impact test to draw some conclusion from the tested material, even if care is taken to perform it.

As the results of several specimens of the same material may vary from among themselves, it is necessary to do at least three tests to have an acceptable average as a result. Every three specimens from the same location is called a set, for example: 1 weld set, 1 ZAC set etc...

As in the tensile test, it is also possible to estimate the ductility of the material only by observing the fractured region of the test body. The higher the percentage of shear, the more dubious the material (see traction topic).

Evaluation of results

The evaluation criteria for this assay are:- Energy absorbed by the test body. The energy absorbed in the tested specimens is read on the machine display;

- The characteristic and percentage of the fracture (dubious or fragile). The percentage of shear is a function of the area of the fracture part that has a bright aspect.

- Percentage of lateral expansion of the test body. The lateral expansion is the addition of the opposite face to the notch, in the direction of the notch itself, after the rupture of the test body. This criterion is very rare and is almost never required.

Energy is calculated by varying the potential energy of the hammer (component of the impact test machine) before and after impact. Remember that the lower the energy absorbed, the more fragile the material at that temperature.

See the figure below examples of charpy specimens:

- cp not tested (below);

- cp after test (of the medium);

- cp/very dubious material (from above);

The evaluation of the test results shall be in accordance with the standard, specification or design in which the acceptable mean and minimum values are defined to consider the tests as approved.

COMMENTS